Polytetrafluoroethylene (PTFE) Mesh for Gas-Liquid Filtration: A Superior Solution for Corrosive Environments

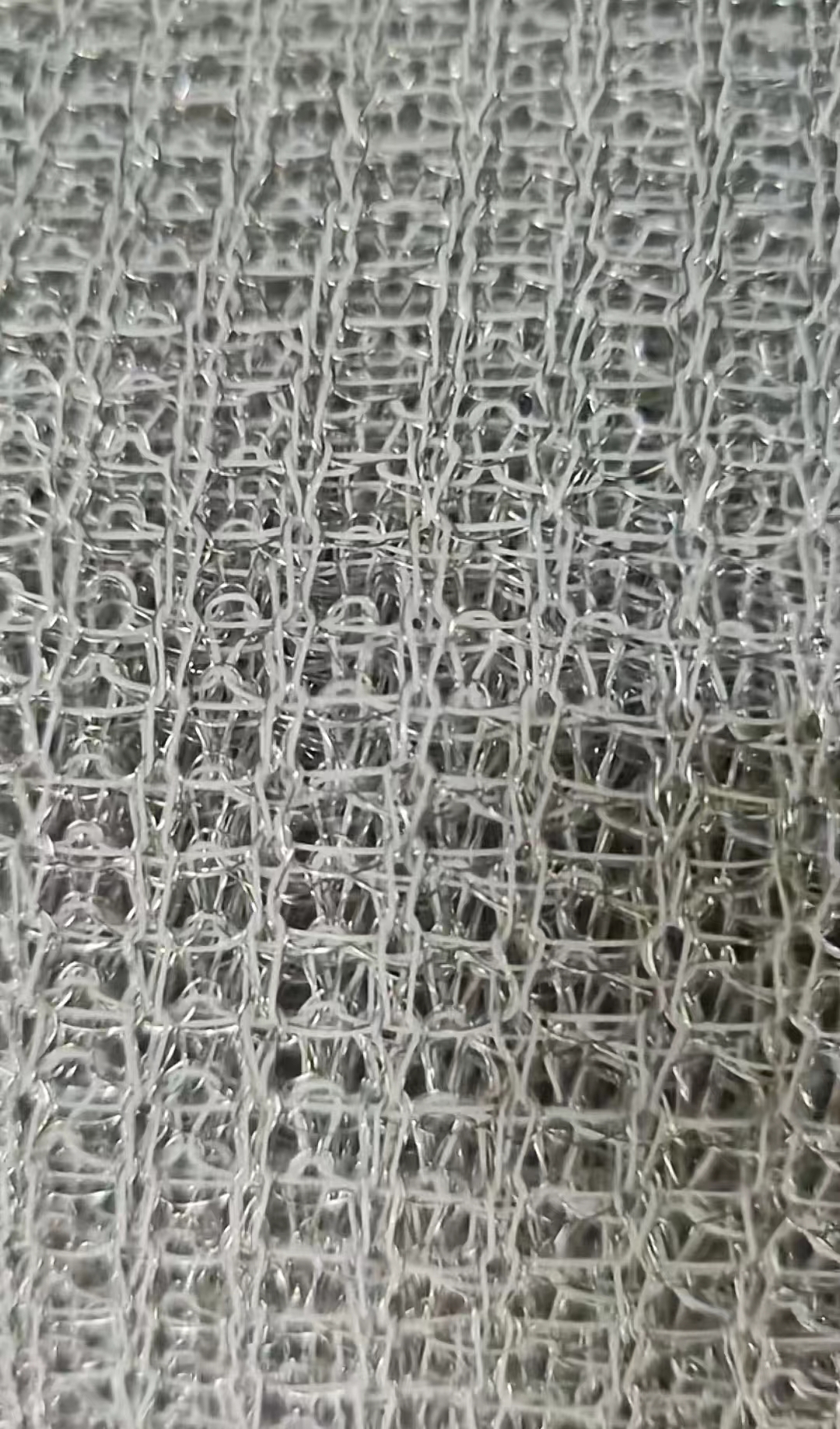

PTFE mesh is made from high-quality PTFE monofilament with a diameter ranging from 0.10mm to 0.55mm. It is available in various weaving styles, including knitting, single-strand, double-strand, and multi-strand. The mesh can be customized to meet specific requirements in terms of size and width, with options ranging from 40mm to 600mm.

Performance:

PP knitted wire mesh for filtering and separating

1. Chemical Stability: PTFE mesh exhibits excellent chemical resistance, making it impervious to strong acids, strong bases, and organic solvents. It remains unaffected by even the most aggressive chemicals, including hydrofluoric acid, phosphoric acid, sulfuric acid, and a wide range of organic acids and solvents.

2. Thermal Stability: With a pyrolysis temperature above 400°C, PTFE mesh can operate reliably within a temperature range of 200°C to 300°C. It can withstand extreme temperatures up to 250°C, making it suitable for high-temperature and harsh chemical environments.

3. Low Friction: The coefficient of friction for PTFE is exceptionally low, at only 0.02, which is 1/40th that of rubber. This property makes PTFE mesh an ideal choice for applications where reduced friction is crucial.

4.PTFE (polytetrafluoroethylene) mesh cloth surface has excellent self-lubricating properties, can prevent almost all sticky substances attached to it. However, when PTFE is combined with stainless steel wire in a multi-weave way, the resulting oil smoke filter (air filte) not only improves the adsorption capacity, but also achieves a more effective filtration effect than the traditional metal mesh.

Cotton and metal wire mixed knitted mesh

Advantages:

PTFE mesh stands out as one of the best mist-removal products in terms of corrosion resistance. It can withstand the harshest acid and alkali media, making it highly durable and reliable. PTFE mesh is uniquely capable of withstanding the effects of concentrated sulfuric acid and nitric acid mixtures, which are notorious for their corrosiveness. This level of performance is unmatched by other plastic gas-liquid filter meshes. The material used is imported high-purity PTFE wire.

Conclusion:

PTFE mesh is an exceptional choice for gas-liquid filtration applications, especially in corrosive environments. Its unique combination of chemical resistance, thermal stability, low friction, and non-adhesive properties make it an invaluable material for a wide range of industries. With our extensive experience and commitment to quality, we are proud to offer a superior solution that meets the demanding requirements of modern filtration systems.

PTFE Knitted Mesh with Excellent Resistant to Strong Acids and Bases

Glass fiber metal wire knitted mesh